The Creality K1 High Speed 3D Printer represents a significant departure from the brand’s traditional budget-focused approach, positioning itself as a high-speed flagship model that challenges established competitors in the fast-printing segment. After extensive testing and analysis, this comprehensive review examines whether Creality’s latest offering delivers on its ambitious promises of speed, quality, and value.

Introduction: Creality’s Speed Revolution

Creality has built its reputation on affordable, reliable 3D printers, particularly the beloved Ender series. However, the rapid evolution of 3D printing technology, particularly the emergence of high-speed CoreXY machines, has pushed the manufacturer into uncharted territory. The K1 represents Creality’s answer to the growing demand for fast, reliable printing without the premium price tag typically associated with such capabilities.

The printer enters a competitive market dominated by Bambu Lab’s offerings, particularly the X1 Carbon and P1P, which have set new standards for speed and ease of use. At its launch price of approximately £500-600, the K1 positions itself as a more affordable alternative whilst attempting to match the performance characteristics that have made its competitors so popular.

Design and Build Quality

Exterior Design and Enclosure

The K1 adopts a fully enclosed design philosophy, housing its CoreXY mechanics within a sleek, modern chassis that measures 355 x 355 x 480mm. The enclosure serves multiple purposes: it provides temperature stability crucial for printing advanced materials like ABS and ASA, reduces noise levels, and creates a professional appearance suitable for office environments.

The machine’s aesthetic clearly draws inspiration from contemporary high-end 3D printers, featuring clean lines and a predominantly black colour scheme. Glass panels on the sides and front provide excellent visibility of the printing process whilst maintaining the enclosed environment. The build quality feels solid, with sturdy construction that inspires confidence in long-term reliability.

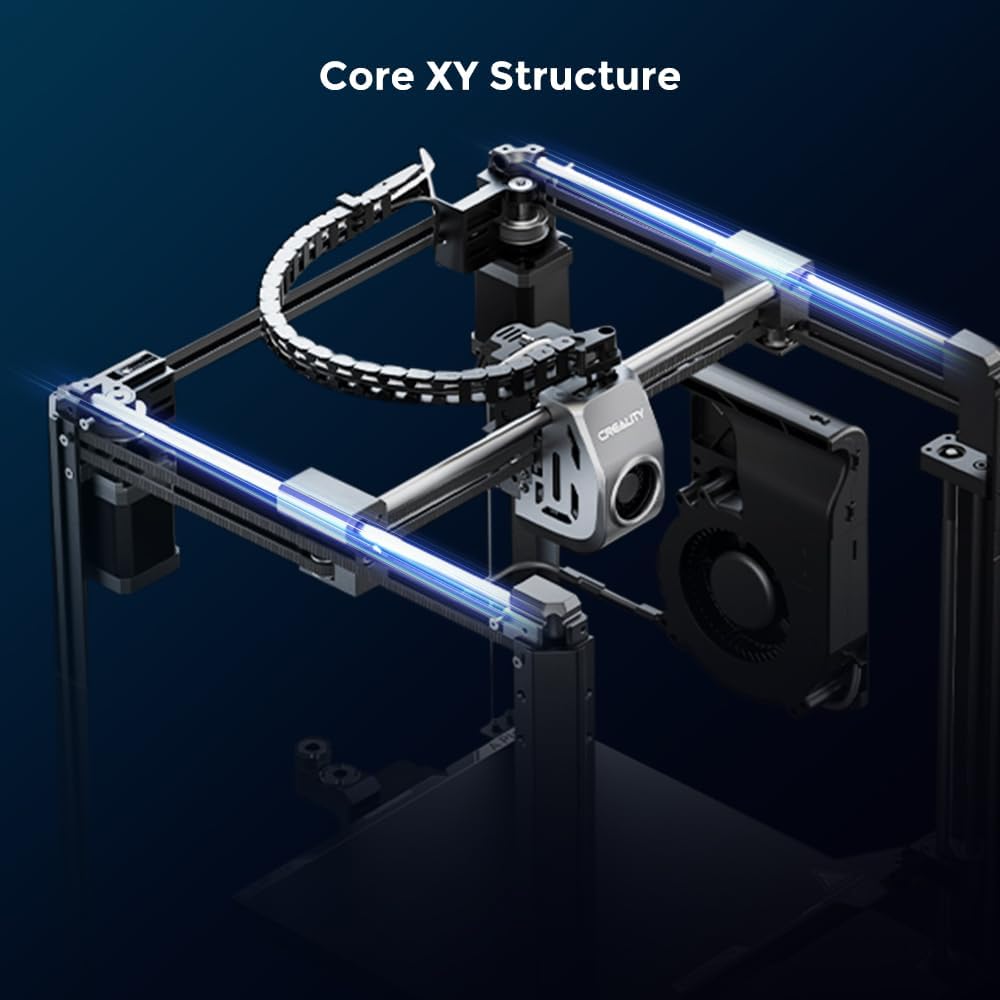

CoreXY Motion System

At the heart of the K1 lies a CoreXY motion system, a significant upgrade from the traditional Cartesian mechanics found in Creality’s previous offerings. This design choice enables the impressive speeds the machine is capable of achieving. The motion components appear well-engineered, utilising polished metal rails and components that should provide longevity even under intensive use.

The implementation includes automatic input shaping and vibration compensation, technologies that help maintain print quality even at high speeds. During testing, the system demonstrated excellent precision, producing dimensionally accurate prints with minimal layer inconsistencies.

Build Platform and Print Surface

The K1 features a 220 x 220 x 250mm build volume, identical to the popular Ender 3 series. Whilst not the largest available, this size accommodates most typical 3D printing projects whilst keeping the machine’s footprint reasonable for desktop use. The build platform utilises a flexible steel sheet with a proprietary coating that requires the use of adhesion aids such as glue stick for optimal first-layer adhesion.

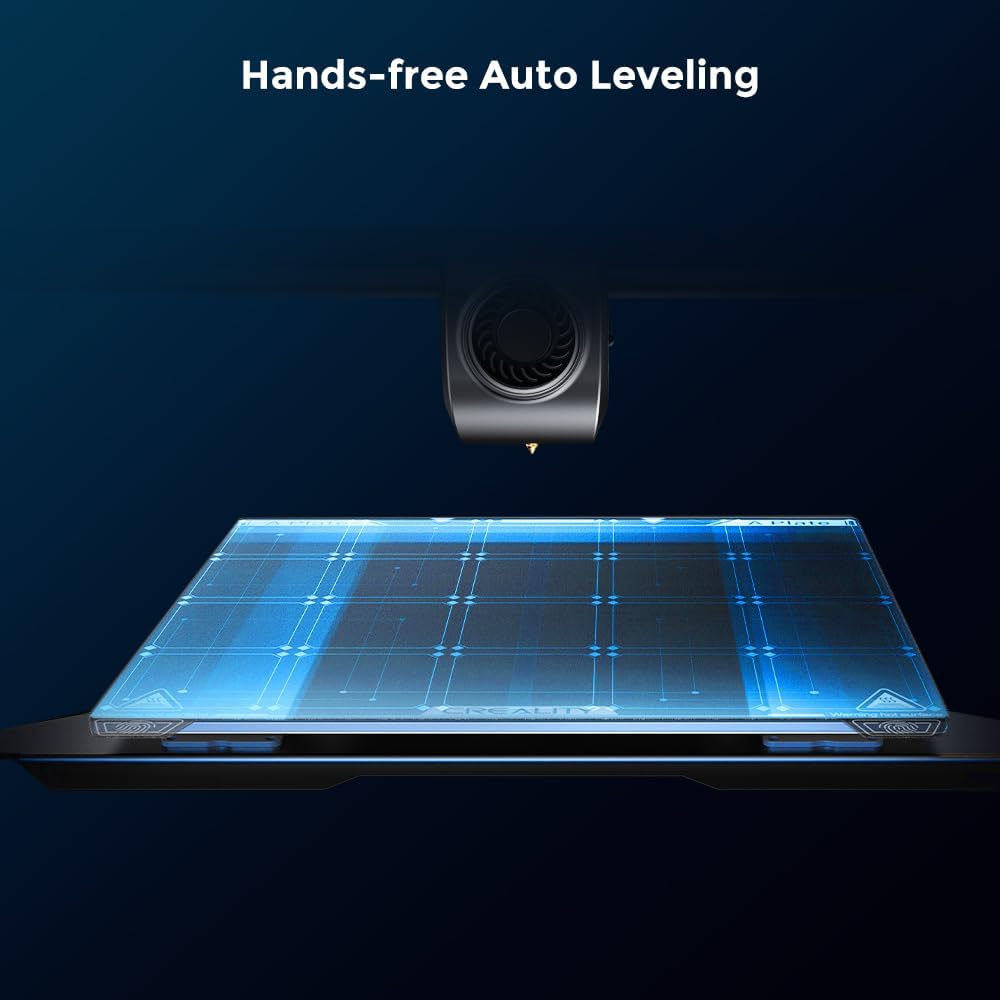

The platform includes notched edges similar to those found on the Ender 5 S1, potentially making replacement plates more accessible. The automatic bed levelling system uses multiple probe points to ensure consistent first-layer adhesion across the entire surface, though some users have reported occasional drift that requires recalibration.

Performance Analysis

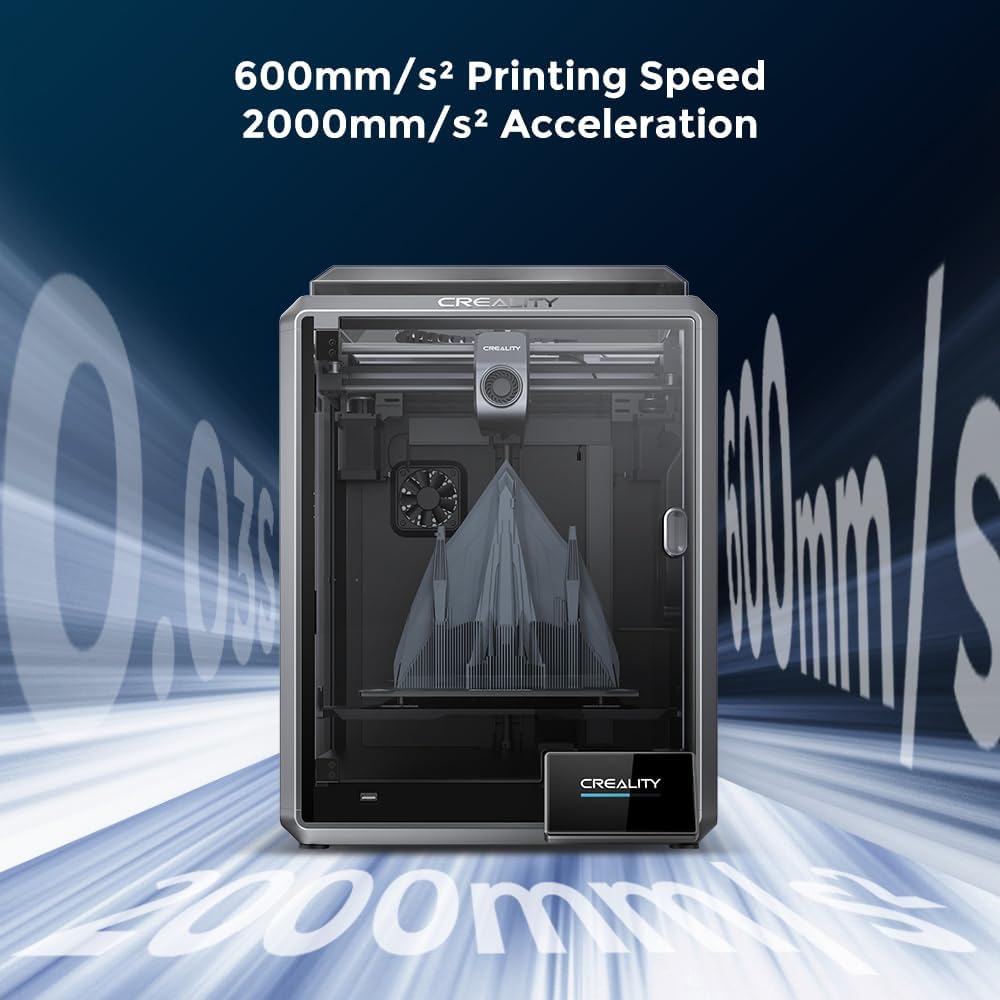

Speed Capabilities

The standout feature of the K1 is undoubtedly its speed capabilities. Advertised as capable of reaching 600mm/s printing speeds with 20,000mm/s² acceleration, the machine delivers impressive real-world performance. In practical testing, most prints utilise speeds around 300mm/s as default, which still represents a substantial improvement over traditional FDM printers.

Comparative testing demonstrates the speed advantage clearly: a standard 3DBenchy that would typically require 55 minutes on an Ender 3 S1 running at its maximum 100mm/s completes in approximately 23 minutes on the K1. This represents more than a 50% reduction in print time whilst maintaining comparable or superior quality.

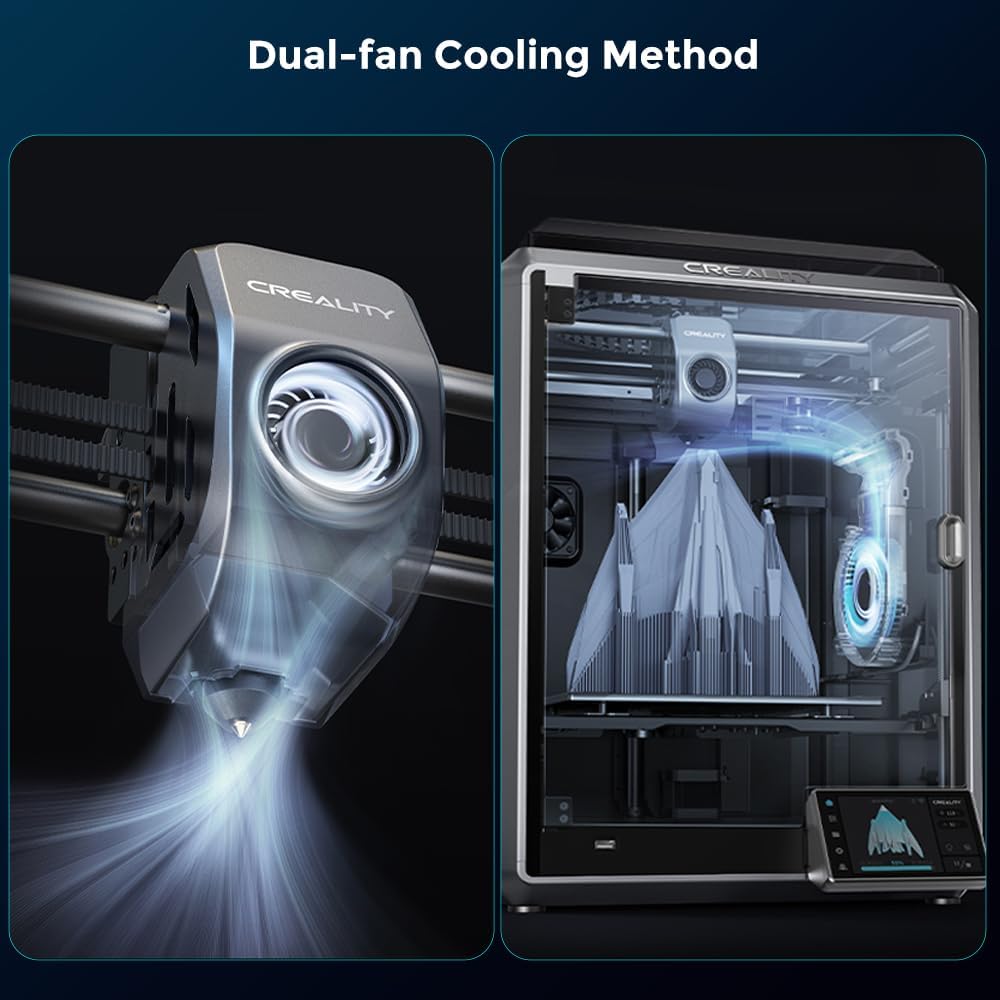

The speed improvements extend beyond simple geometric models. Complex prints with overhangs, bridges, and intricate details benefit from the machine’s advanced cooling system and motion control, allowing users to maintain high speeds without sacrificing quality.

Print Quality Assessment

Despite its focus on speed, the K1 demonstrates impressive print quality across various test models. Layer adhesion appears excellent, with smooth surface finishes and minimal visible layer lines when printing at standard 0.2mm layer heights. Overhangs print cleanly thanks to effective part cooling, whilst bridging performance exceeds expectations for a machine in this price category.

Detail reproduction varies depending on the model complexity and print settings used. Fine details such as text and small features may require slower speeds or higher resolution settings, but this represents a reasonable trade-off given the machine’s speed-focused design philosophy.

The printer handles dimensional accuracy well, with test prints consistently meeting expected tolerances. Moving parts and print-in-place mechanisms function smoothly, indicating proper calibration and consistent extrusion throughout the printing process.

Material Compatibility

The K1 demonstrates versatility across a range of 3D printing materials. PLA performance is exemplary, particularly when using Creality’s own Hyper PLA formulation designed for high-speed printing. The enclosed chamber and heated bed support ABS and ASA printing effectively, producing warp-free results that would challenge open-frame printers.

PETG compatibility is excellent, with the machine’s temperature control and cooling systems managing this notoriously stringy material well. TPU performance proved disappointing in testing, requiring significant flow rate adjustments to achieve acceptable results, which may indicate room for improvement in the flexible filament profiles.

The machine’s maximum hotend temperature of 300°C opens possibilities for engineering materials, though the standard 0.4mm nozzle may limit flow rates for some applications.

Software and User Experience

Klipper Firmware Implementation

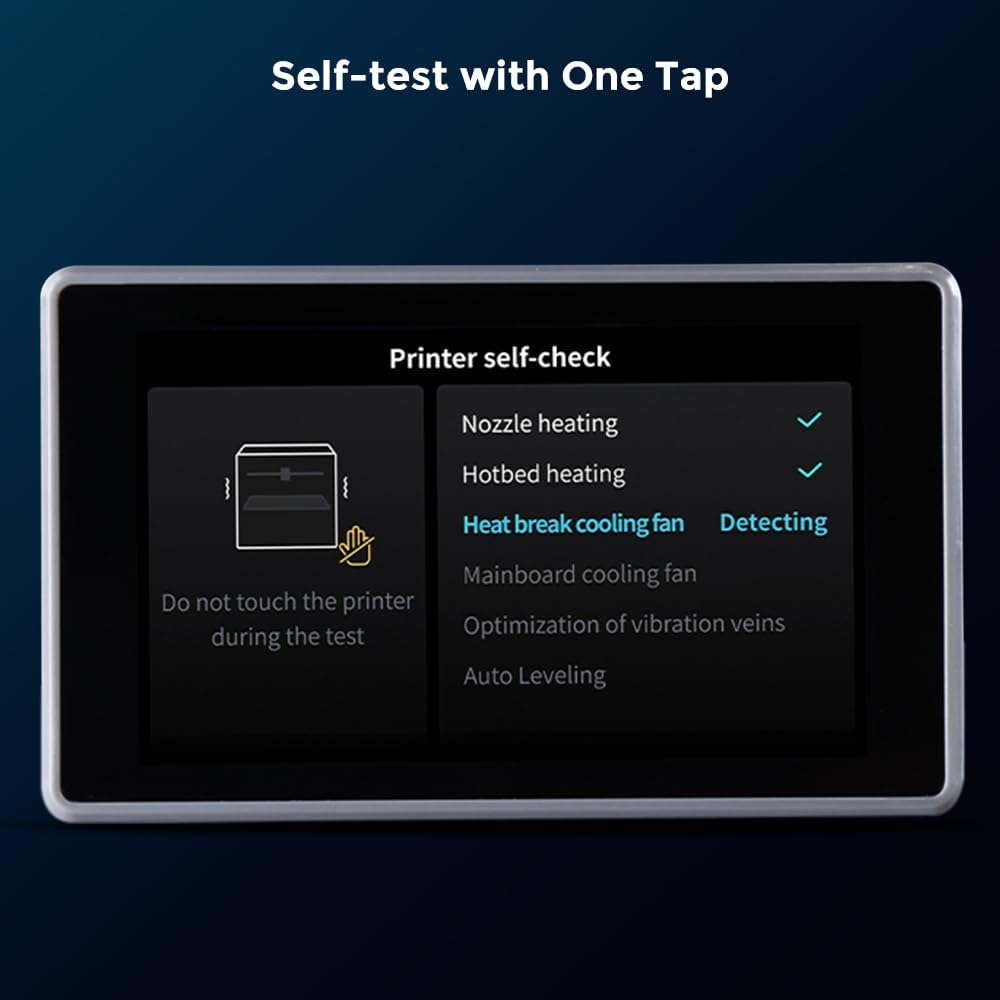

The K1 runs a modified version of Klipper firmware, which Creality has customised for their specific implementation. Whilst Klipper typically offers extensive customisation options, Creality’s version limits access to certain advanced features, presumably to maintain user-friendliness for less experienced operators.

This approach presents both advantages and disadvantages. New users benefit from a simplified interface that handles complex calibration procedures automatically. However, experienced users may find the locked-down nature frustrating, particularly those familiar with Klipper’s full capabilities.

The firmware handles automatic bed levelling, input shaping, and thermal management competently, requiring minimal user intervention for routine operation. The system remembers previously printed files, which proves convenient for repeat jobs or when travelling with the printer.

Creality Print Software

The accompanying Creality Print slicer provides a user-friendly interface with pre-configured profiles for various materials and quality settings. The software includes useful features such as print thumbnails that display on the printer’s screen, making job selection more intuitive.

Profile settings appear well-tuned for the machine’s capabilities, though users familiar with other slicers may need time to adapt to the different layout and terminology. The software supports multiple connection methods, including USB, WiFi, and cloud-based printing through Creality’s online service.

Users preferring established slicers like PrusaSlicer or Cura will need to create their own profiles initially, as pre-configured settings weren’t available at launch.

Connectivity Options

The K1 offers multiple connectivity options that cater to different user preferences and workflows. USB flash drive support provides the most reliable method for file transfer, eliminating potential network issues. WiFi connectivity enables convenient remote monitoring and job initiation, whilst the cloud service option allows access from anywhere with internet connectivity.

The local area network (LAN) functionality represents perhaps the best balance, providing remote access without relying on external cloud services. This approach addresses privacy concerns whilst maintaining convenience for users with appropriate network infrastructure.

Assembly and Setup Experience

Unboxing and Initial Assembly

Creality’s packaging approach for the K1 demonstrates attention to protecting the enclosed printer during shipping. The machine arrives in a wooden crate with internal cardboard packaging, providing excellent protection for the glass panels and precision components.

Initial setup requires minimal assembly, with the machine arriving approximately 99% pre-built. Users need only connect the touch screen, install the filament holder, remove shipping restraints, and perform initial calibration. The process typically takes less than an hour, making the printer accessible even to newcomers to the hobby.

The included documentation provides clear instructions, supplemented by helpful video tutorials that guide users through the setup process step-by-step.

Calibration and First Prints

The automatic calibration process impresses with its thoroughness and reliability. The machine performs bed levelling, input shaping calibration, and thermal characterisation with minimal user intervention. This automation removes much of the complexity traditionally associated with high-performance 3D printers.

The included sample of Hyper PLA enables users to complete their first print immediately after setup. Pre-sliced test models provide confidence-building results that demonstrate the machine’s capabilities whilst users familiarise themselves with the software and workflow.

Comparative Analysis

Versus Bambu Lab Competitors

The most direct comparison lies with Bambu Lab’s offerings, particularly the P1P and X1 Carbon. The K1 matches these machines’ speed capabilities whilst offering a fully enclosed design at the P1P’s price point. However, Bambu’s ecosystem integration, multi-colour capabilities (with upgrades), and refined user experience still represent advantages.

The K1’s use of standard components and open-source foundation may appeal to users preferring repairability and customisation options. Bambu’s proprietary approach, whilst delivering excellent out-of-box experience, may concern users thinking long-term about parts availability and modifications.

Traditional Creality Alternatives

Compared to Creality’s established Ender series, the K1 represents a substantial step forward in capabilities. The speed improvements, automatic features, and enclosed design justify the higher price for users prioritising productivity and advanced material compatibility.

Users satisfied with PLA printing and comfortable with manual calibration may find better value in updated Ender models, particularly when considering upgrade paths and community support.

Advantages and Strengths

The K1’s primary strength lies in its speed-to-price ratio. Few printers in this price range offer comparable printing speeds whilst maintaining reasonable quality standards. The enclosed design enables reliable printing of temperature-sensitive materials that would challenge open-frame alternatives.

The automatic calibration systems work reliably, reducing the technical barriers typically associated with high-performance printers. The multiple connectivity options accommodate various workflow preferences, whilst the solid mechanical construction suggests good long-term reliability prospects.

Print quality at speed impresses consistently, with the cooling systems and motion control delivering results that compete with much more expensive alternatives.

Limitations and Areas for Improvement

The modified Klipper implementation, whilst user-friendly, may frustrate experienced users seeking advanced customisation options. The proprietary nozzle design complicates upgrades, though compatibility with standard Volcano nozzles provides some flexibility.

The rear-mounted spool holder design proves awkward in practice, requiring machine rotation for filament changes. This represents a significant workflow impediment compared to side-mounted or top-feeding alternatives.

TPU printing performance disappointed in testing, requiring significant adjustments to achieve acceptable results. This limitation may concern users planning to work extensively with flexible materials.

The requirement for adhesion aids on the standard build surface adds complexity to the printing process and ongoing consumable costs.

Value Proposition and Market Position

At its current pricing, the K1 delivers exceptional value for users prioritising speed and enclosed printing capabilities. The combination of CoreXY mechanics, automatic calibration, and multi-material compatibility typically commands significantly higher prices from established manufacturers.

The machine particularly suits users transitioning from entry-level printers seeking substantial capability improvements without premium pricing. Small businesses and educational institutions may find the productivity improvements justify the investment, particularly when printing time represents a significant operational constraint.

Hobbyists comfortable with the limitations and seeking fast, reliable printing for standard materials will likely find the K1 an attractive proposition.

Long-term Considerations

The K1’s use of standard mechanical components and open-source firmware foundation suggests reasonable long-term supportability. Creality’s established service network and parts availability provide confidence in ongoing support, whilst the active user community developing around the K1 series promises continued improvement and customisation options.

The machine’s design appears suitable for upgrade and modification, though Creality’s approach to firmware updates and feature additions remains to be demonstrated over time.

Recommendations and Use Cases

The K1 suits users seeking fast, reliable printing with minimal technical intervention. It particularly excels for:

- Small businesses requiring quick prototyping capabilities

- Educational environments emphasising productivity over customisation

- Hobbyists upgrading from entry-level printers

- Users frequently printing ABS or ASA materials

- Applications where print speed significantly impacts workflow

The machine may not suit:

- Users prioritising maximum customisation and control

- Flexible filament specialists

- Those requiring the largest possible build volumes

- Users preferring completely open-source solutions

Future Outlook and Ecosystem Development

The K1 represents the first iteration of Creality’s high-speed platform, with the larger K1 Max and enhanced K1C variants already available or announced. This suggests ongoing development and refinement of the core technology, potentially addressing current limitations through future updates.

Creality’s commitment to maintaining compatibility with open-source tools and providing eventual access to full Klipper functionality indicates awareness of community concerns. The success of the K1 series will likely influence the direction of Creality’s future product development.

Conclusion

The Creality K1 High Speed 3D Printer successfully achieves its primary objective: delivering high-speed 3D printing capabilities at an accessible price point. Despite some limitations in software flexibility and material handling, the machine provides exceptional value for users prioritising speed, reliability, and ease of use.

The K1’s combination of CoreXY mechanics, automatic calibration, and enclosed design creates a compelling package that challenges established competitors whilst remaining financially accessible to a broader audience. Print quality at speed consistently impresses, justifying the “high-speed” designation whilst maintaining the reliability expected from Creality products.

For users seeking substantial capability improvements over traditional FDM printers without premium pricing, the K1 represents an excellent choice. Its limitations, whilst notable, don’t fundamentally compromise the machine’s core value proposition of fast, reliable printing with minimal technical barriers.

The Creality K1 High Speed 3D Printer earns recommendation for users whose priorities align with its strengths: speed, enclosed printing, and user-friendly operation. As Creality’s first serious entry into the high-speed 3D printing market, it establishes a strong foundation for future development whilst delivering immediate value to users ready to embrace faster, more capable 3D printing technology.

Buy Now on Amazon

Click below to purchase securely with fast delivery.

This post contains affiliate links. If you click on a link and make a purchase, I may earn a small commission at no extra cost to you. This helps support the blog and allows me to continue providing content. Thank you for your support!